Test platforms

Whether for thermal, thermodynamic, ventilation, air diffusion or acoustic tests, the multi-purpose facilities operated by CETIAT meet the needs of industrial partners.

OUR THERMAL TESTING FACILITIES

- boilers using gas, oil, wood, etc,

- solid fuel stoves and insets (logs, pellets, shredded wood, etc.),

- hot water radiators,

- solar thermal collectors and domestic solar water heaters,

- pipes, fittings and valves for gas-fired equipment.

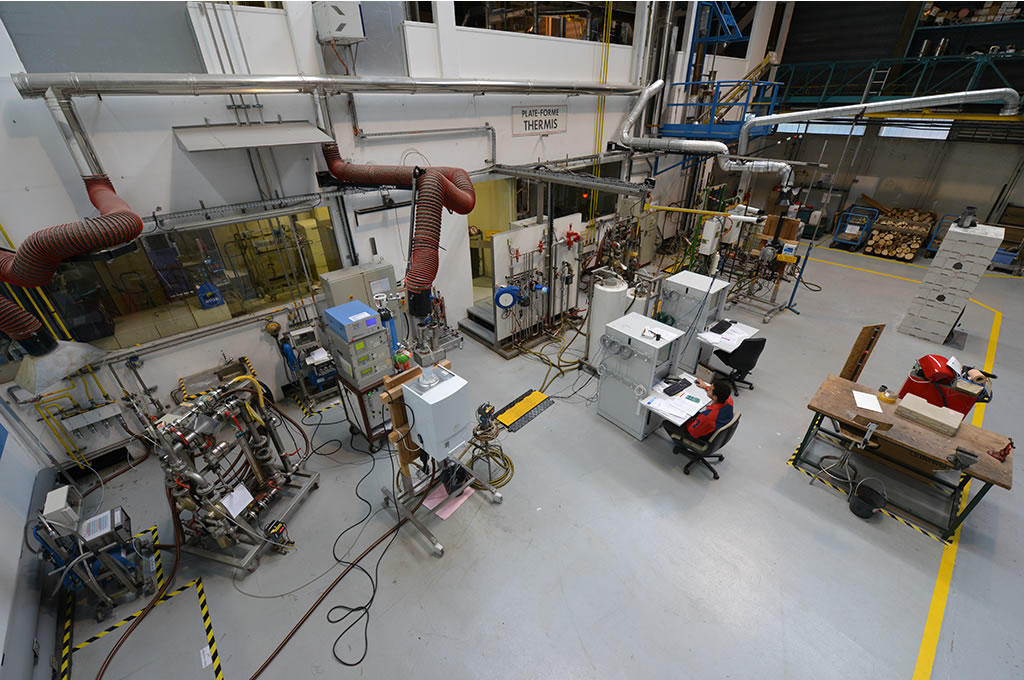

THERMIS platforms

This collection of six platforms enables tests related to thermal performance, safety and fitness for use on boilers (all fuels), stoves and insets. Laboratory output capacity goes up to 400 kW, beyond which tests are carried out on-site or at the manufacturer's premises.SOLAR platform

Here we carry out natural sunlight testing of solar collectors and domestic solar water heaters.RADIATORS platform

This platform is where we test all types of hot water radiators.

GAS COMPONENTS laboratory

This laboratory is equipped with the necessary mechanical, physical and chemical equipment to test flexible hoses, fittings and valves for gas-fired appliance connections.

INDUSTRIAL THERMAL TESTING FACILITIES (ERICA)

Unique in Europe, ERICA is a scalable testing and measurement platform dedicated to radiant energies (ultraviolet (UV), infrared (IR), microwaves (MW) and radio-frequencies (RF)).

ERICA assists industrial firms in integrating radiant technologies into their manufacturing processes, from feasibility studies right through to operational deployment.

THERMODYNAMIC TESTING FACILITIES

- heat pumps (water/water, glycol water/water, air/water, water/air and ground source),

- chillers or liquid cooling packages (water/water and air/water),

- components of a refrigeration system: compressor, exchanger, expansion valve etc.,

- fan coil units.

| Platform name | Dimensions (m) | Number of zones | Climates | Power (KW) |

|---|---|---|---|---|

| Clim 3 | 6,5x11,6x7,25 | 1 | Dry temperature -15 to +55°C Dew point -15 to +40°C |

100 |

| Echangeur | 6x12x6 | 2 | Dry temperature -15 to +55°C Dew point -15 to +40°C |

50 |

| Clim 1 | 6,3x11,5x6,5 | 2 | Dry temperature -15 to +55°C Dew point -15 to +40°C |

30 |

| Multifonction | 2 | Dry temperature -15 to +55°C Dew point -15 to +40°C |

15 |

VENTILATION AND AIR DIFFUSION TESTING FACILITIES

- unidirectional (exhaust) and bidirectional (heat recovery) mechanical ventilation units,

- unidirectional (exhaust) and bidirectional (heat recovery) air handling units (AHU), with or without heat recovery,

- plate or rotary air/air exchangers for AHU,

- heating or cooling air/water coils for AHU,

- ducts, terminals, diffusers and air inlets,

- fans,

- filters.

AHU

This platform serves to determine the aerodynamic, thermal, acoustic and/or mechanical performance of air handling units (up to 15,000 m3/h) and their components, such as air/air heat exchangers or air/water cooling or heating coils (up to 10,000 m3/h).VENTILATION COMPONENTS

These platforms feature airflow generation and measurement instruments to determine the flow-pressure curves of ventilation system components..AIR DIFFUSERS

This platform serves to qualify the performance of air diffusion components or ventilation systems to characterise ambient comfort (temperature and airflow mapping).VENTILATION COMPONENTS

These platforms feature airflow generation and measurement instruments to determine the flow-pressure curves of ventilation system components.FILTERS

These platforms enable us to test general ventilation filters and gas filters.

ACOUSTIC TESTING FACILITIES

These resources are dedicated to the acoustic characterisation of HVAC engineering equipment

| Platform name | Volume ( m3) |

Features | Type of tests |

|---|---|---|---|

| REVERB 1 | 550 | Reverberation room Tests according to ISO standard |

Sound power of fans measured at the same time as the airflow/pressure curve |

| REVERB 2 | 2x200 | Double reverberation room | Sound power of split heat pumps, fan units, air outlets and inlets |

| REVERB 3 | 203 | Reverberation room | Sound power of boilers (all fuels) and fan coil units |

| SESAME | 124 | Semi-anechoic chamber Sound intensity and pressure measurement |

Acoustic diagnostics and localisation of noise sources for boilers and ventilation equipment (max. 1000 m3/h) |

|

Other |

Intensity measurement | Sound power of chillers, heat pumps, boilers |